Textile dividers

Product information

Products with delicate surfaces or finishes require high care. Protection is necessary even when they are shipped in a closed transport loop. Many companies struggle to pack them one by one. Employees spent time and effort to enclose the goods inside single-use bubble wrap, plastic foil and cardboard sheets. Such operations translate into low productivity. And their overall costs increase. Additionally, it is more difficult for them to achieve their environment goals.

We adapt the interior of the secondary packaging to every batch of sensitive items. We use high-quality technical fabrics and the right design. Our solutions consist of textile dividers. They ensure safe and gentle storage of the goods. The used material enables optimum protection of the item’s surfaces. Each product enters into a textile slot. In this way, the goods do not touch each other. Also, they do not touch the walls and bottom of the secondary packaging.

Every project is unique. And technical materials offer numerous customization possibilities. We design fabric packaging according to customers’ needs and requirements. We optimize the packaging space and increase the number of packed parts per unit. In this way, the textile packaging accommodates, in a separate form, the highest number of pieces per package.

What are textile dividers?

Textile dividers are custom-made packaging solutions for sensitive parts. They incorporate flexible yet very protective materials. They are sewn to form pockets with different dimensions. These compartments keep each item in place. Arrangement of items is possible in horizontal or vertical directions. Apart from the protective purposes, textile pockets accommodate more products in the same packaging. Thus, the volume of the packed products reaches a maximum level.

Textile separators brace the parts with soft materials. Their smooth surface prevents damage caused by scratches and dust. Due to their highly protective qualities, they keep the products safe for many trips. They are reusable and can last through the lifetime of the project. Such advantages constantly add value to the supply chain. The protection extends not only during transport but also along many internal processes. Among them, there are handling, assembly and storage.

Packaging textile pockets allow the operators to insert and remove the parts easily. If necessary, they can change only the insert. This will enable them to pack different components in one container. Additionally, we can design the pockets as a universal packing solution. The option allows companies to standardize their returnable packaging. Thus they lower even more packaging costs.

Textile inserts are available in different materials, densities and colours. They are specially designed to transport parts with sensitive, painted or finished surfaces. The range comprises woven and unwoven materials such as Spunbond, Evolon and Tyvek. For the electronic industry, we use antistatic (ESD) versions. Other particular applications can include fireproof and waterproof characteristics. Lamination and coatings are also possible.

Textile dividers are:

- Light weighted yet durable

- Thin yet strong

- Soft to the touch

- Flexible and breathable

- Adaptable to any industrial sector

- Easy to use

- Completely customizable in terms of sizes

- Ergonomic

Textile dividers stand out for:

- High protection of the goods

- Maximum packing density

- Decreased transport expenses

- Reduced total costs of ownership

- Quick handling

- Improved workflow

- Tool-free manufacturing

- Countless design possibilities

Design possibilities

Reusable textile packaging is entirely customizable in terms of sizes and fabrics. Textile materials are strong and versatile. They enable us to create diverse and innovative shipping packaging solutions. Custom-made textile dividers are fix or foldable to save space. Depending on the secondary packaging, we can construct it on multiple levels on sliders. For extra rigidity, we provide the structure with metal bars or plastic panels. We can also combine additional materials such as PVC and technical foams. They offer increased protection for the components. Velcro closures, side skits, double bottoms and reinforced edges are just a few of the options.

Textile dividers for trays and crates

Textile dunnage is fixed on secondary packaging like trays and crates. This eliminates the use of more complex assemblies formed by separate parts. A significant characteristic of the solution is that the insert can remain a part of the box. This happens even when folded. Also, the insert does not need to be stored separately. Such advantages save essential space. They also prevent losing or damaging the inserts when being removed. The design offers a simple replacement of dunnage for subsequent projects. For increased parts protection, we can provide the inserts with fixed or loose covers.

The trays and boxes can be rigid or foldable. Suitable models include KLTs and completely customized solutions. We can manufacture customized trays and crates from corrugated or hollow chamber plastic sheets. Our customers use these solutions for small and medium-sized parts and components. For the electrical engineering industry, we recommend antistatic textile separators.

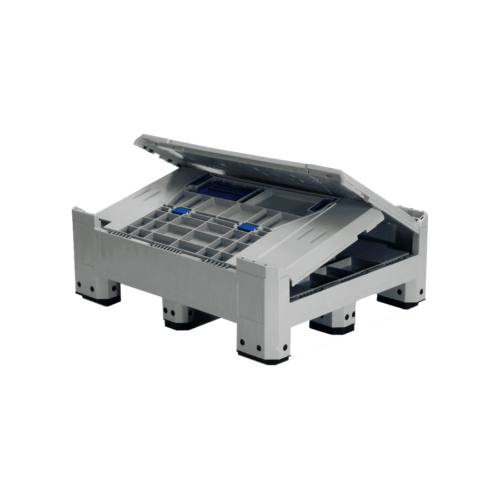

Textile dividers for large containers

Standard or custom-made plastic and metal containers suit medium and large parts. They are also efficient for heavier items. The range comprises standard foldable large containers (FLC) and customized versions. We use honeycomb structure core panels, steel and combinations for custom-made containers. Large containers ensure optimum partitioning and protection for the components. Combined with the inserted textile compartments, they withstand multiple folding and unfolding cycles. Due to their robustness, they are most suitable for long-distance logistic loops.

The parts stay individually in hanging pockets. Suspension is possible through the mounted metal sliding rails. Textile dunnage compartments can incorporate different bars to stiffen the sliding connection. Thanks to the sliding system, the goods can hang on multiple levels. The optimized number of layers generates a higher number of packed items. We can provide the solution with PVC covers to add protection during transport and storage.

Sliding textile separators allow the operators to access all the parts from all the layers easily. Large containers allow front and lateral access. The doors and openings facilitate manipulation and speed up goods’ loading and unloading. Despite their dimensions, only one employee can easily handle them. This advantage reduces labour efforts and ergonomic concerns.

Textile dividers for shipping racks and carts

Companies use modular racks and packaging carts mainly for short logistic loops. The solutions refer to metal pipes and frames that incorporate soft textile dunnage. Depending on the application, we can provide them with shelves and walls made of honeycomb plastic panels. We can use other durable fabrics such as PVC and PE for lids or antidust curtains. These materials are transparent or opaque. Sewing the covers to the insert ensures their fixation. Alternatively, they can be removable. Optional velcro or zip fastening is available to close the lids or the access doors.

The racks can be foldable to save return transport costs. Different suspension systems prevent damaging the flexible internal dunnage by strain during folding. The packing racks move on wheels. The wheels present brakes and release functions for easier manipulation. Different printing solutions are also available to mark the racks and carts with product or brand information.

Textile dividers for intralogistics

We can design tugger train trolleys and WIP (Work in Progress) carts for internal material flow. These solutions transfer unfinished items between different production and assembly places. They improve the workflow and protect the items during moving and storing. Operators can easily remove the spunbound dividers to clean the shelves. Textile compartments are universal so that they can fit multiple parts. These racks present wheels for quick maneuvering.

Intralogistics carriers with dunnage textile compartments offer a high level of stability. Their design is unique in terms of sizes and materials. The shelf inserts contain honeycomb structured core plates and technical foams encased in textiles. The plastic plates stiffen the base, shelves and walls. And the foam adds extra cushioning. The racks provide an easy opening and closing through curtains and rolling doors.

Applications

Tier 1 and Tier 2 automotive suppliers are part of a modern and dynamic supply chain. In this role, they must face numerous challenging demands. Many strive to protect valuable and damageable parts while handling or shipping them. Additionally, they must keep their costs as low as possible to ensure profitability. Our fabric separators protect extra delicate components from potential damage and dust. This technological packaging is suitable for both interior and exterior parts and components. Due to its lightweight structure and excellent folding capacity, it also reduces transport costs.

Typical applications include car steering wheels, armrest covers, front grills, instrument clusters and central engine covers. We specialize in offering logistic solutions to industrial sectors. Our experience with different technical materials allows us to propose unique protective packaging. Apart from automotive, we also develop intelligent packaging solutions for the electronic industry, home appliances and other industrial production sectors. Some of their specific applications include air deflectors, engine components and half-axles.